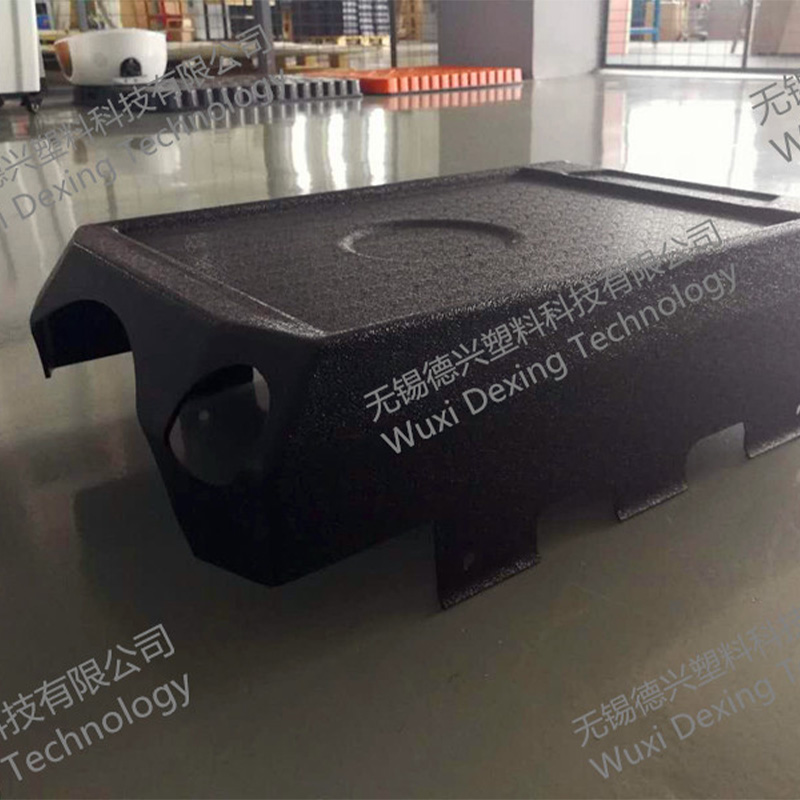

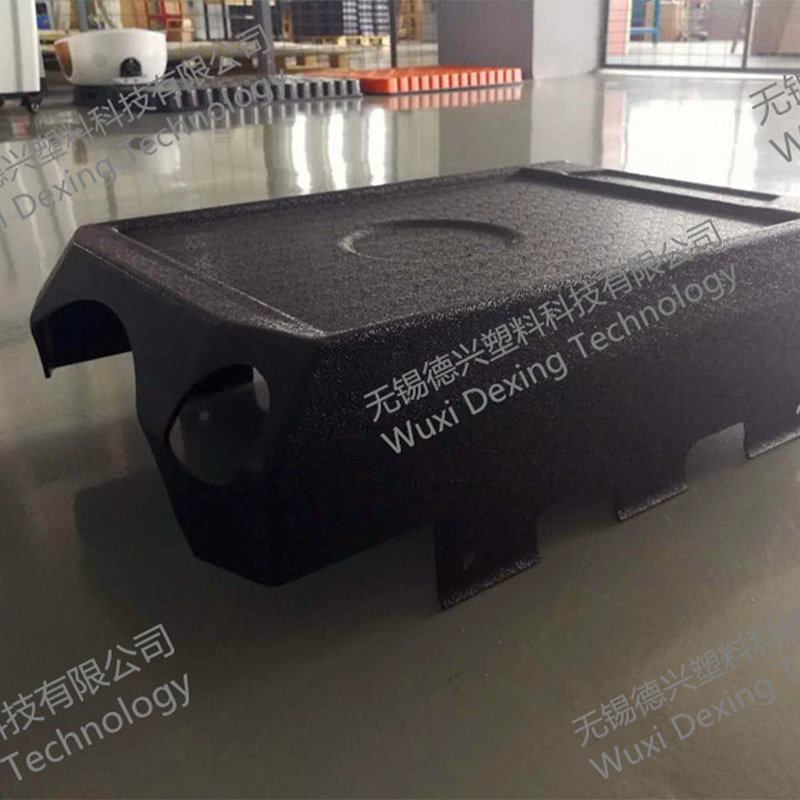

Thick Vacuum Plastic Enclosure For Equiments

Thick Vacuum Plastic Enclosure For Equiments is made by blister process. Its' a kind of Vacuum Forming Plastic Shell For industrial equiment.

The material of the vacuum forming shell is engineering plastic, such as ABS, PC, PVC, PC/ABS, HDPE, and etc.

The appearance of plastic enclosure for equiments can be sprayed and screen printed or without surface treatment according to the design.

Thick Vacuum plastic shell has the characteristics of low mold cost ,short development time and low MOQ.

Details

1. High-Quality Materials for Maximum Strength

The plastic enclosure for equiments is crafted from high-performance thermoplastics, ensuring exceptional impact resistance and longevity.

1.1 Commonly Used Materials

ABS (Acrylonitrile Butadiene Styrene): Known for toughness and shock resistance.

PC (Polycarbonate): Provides high durability and optical clarity.

PVC (Polyvinyl Chloride): Ensures chemical and fire resistance.

PC/ABS Blends: Combines thermal stability with impact resistance.

HDPE (High-Density Polyethylene): Features moisture and chemical resistance.

These materials contribute to the vacuum plastic enclosure, making it highly durable and long-lasting.

2. Advanced Vacuum Forming Process

The thick vacuum plastic is produced through a specialized vacuum forming process, ensuring high precision and efficiency.

2.1 Vacuum Forming Steps

Material Selection: Choosing the best thermoplastic for durability.

Heating Process: The plastic sheet is softened for molding.

Vacuum Forming: The material is shaped over a custom mold to create the vacuum plastic enclosure.

Cooling & Hardening: The shape is solidified for strength.

Trimming & Finishing: Excess material is removed, and custom finishes are applied.

2.2 Benefits of Vacuum Forming

Lower Manufacturing Costs compared to injection molding.

Rapid Production for quick prototyping and mass production.

Seamless Construction for enhanced durability and appearance.

Adjustable Thickness for specific performance needs.

This process ensures the plastic enclosure for equiments is manufactured with precision and durability.

3. Strong and Functional Design

The plastic enclosure for equiments features a robust and user-friendly design.

3.1 Key Features

High-Impact Resistance: The vacuum plastic enclosure withstands mechanical stress and impacts.

Lightweight & Durable: The thick vacuum plastic offers superior protection while maintaining portability.

Chemical & Weather Resistance: Protects against moisture, heat, and UV exposure.

Easy-to-Clean Surface: Ensures a professional and hygienic look.

3.2 Performance Advantages

Supports Heavy Loads: The vacuum plastic enclosure accommodates various components efficiently.

Thermal Stability: The thick vacuum plastic performs consistently in extreme temperatures.

Custom Cutouts & Openings: Designed for cables, displays, and ventilation.

This design makes the plastic enclosure for equiments a perfect fit for demanding industries.

4. Extensive Customization Options

The thick vacuum plastic can be fully customized to fit specific industry requirements.

4.1 Surface Treatments & Branding

Custom Paint & Coatings: Enhances durability and aesthetics.

Screen Printing & Logo Placement: Strengthens brand recognition.

Matte, Glossy, or Textured Finishes: Offers various design preferences.

UV & Chemical-Resistant Coatings: Provides additional protection.

4.2 Structural Customization

Precision Cutouts & Openings: Designed for component integration.

Adjustable Thickness & Reinforcements: Ensures maximum strength.

Modular Design: Allows for easy assembly and maintenance.

These options ensure the vacuum plastic enclosure meets diverse industry demands.

5. Wide-Ranging Industrial Applications

The plastic enclosure for equiments is widely used in various industries, offering reliable protection and functionality.

5.1 Industrial & Automation Equipment

Machine covers and control panel housings.

Protective enclosures for robotics and automation systems.

5.2 Medical & Laboratory Equipment

Medical imaging device enclosures.

Diagnostic and monitoring tool casings.

5.3 Automotive & Transportation

Dashboard and instrument panel enclosures.

Protective casings for vehicle navigation systems.

5.4 Consumer & Commercial Electronics

Kiosk and vending machine housings.

Protective enclosures for smart devices.

5.5 Environmental & Outdoor Equipment

Weather-resistant monitoring device enclosures.

Protective casings for renewable energy systems.

The vacuum plastic enclosure provides versatile and durable solutions for various industry needs.

Conclusion

The thick vacuum plastic is a high-performance and cost-effective enclosure solution for businesses needing reliable and durable vacuum plastic enclosures. The plastic enclosure for equiments offers:

✔ Exceptional durability and impact resistance.

✔ Fast and affordable production using vacuum forming technology.

✔ Customizable designs tailored to industry-specific needs.

✔ Versatile applications across multiple sectors.

For those in need of a high-quality, lightweight, and adaptable plastic enclosure for equiments, the thick vacuum plastic is the ideal choice.

Tags

Get the latest price? We will reply as soon as possible (within 12 hours)